Continuous mandrel extraction with minimum operator effort

This machine is designed to extract tooling from one end

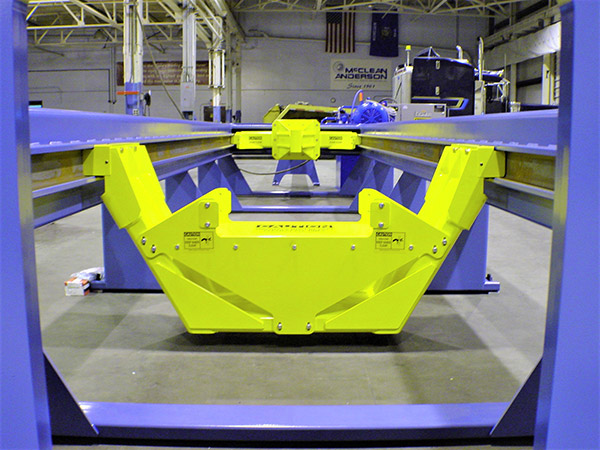

McClean Anderson Mandrel Extraction Systems remove rigid tooling (mandrel) from the inside geometry of a composite product. Depending on the application, Mandrel Extractors can be configured to either push or pull the composite structure from mandrels. The rugged, industrial design allows for continuous extraction with minimum operator effort.

A Control Pendant is used to control and monitor the extraction process. The Control Pendant incorporates an E-Stop switch, start and stop buttons, an extraction speed adjustment knob and two directional buttons.

All machinery is custom built at our facility located is Schofield, WI USA. Machinery framework is of all steel construction with the most robust design in mind.

Mechanical Extraction System:

The puller carriage travels parallel to the mandrel centerline. The carriage is guided by steel bearing guide rollers on steel channel ways. A gear motor that is coupled to a chain and sprocket drive system powers the puller carriage.

Specifications

| Rated Pull Force | 22 kN (5,000 lbf) |

| Puller (Rabbit) Stroke | Standard lengths up to 15.5 meters (610”) |

| Maximum Extraction Envelope | 610mm (24“) |

Hydraulic Extraction System:

The puller carriage travels parallel to the mandrel centerline. The carriage is guided by steel bearing guide rollers on steel channel ways. The carriage puller is hydraulically powered.

Specifications

| Rated Pull Force | 222 kN (50,000 lbf) |

| Puller (Rabbit) Stroke | Standard lengths up to 6.9 meters (270”) |

| Maximum Extraction Envelope | 1219 mm (48“) |