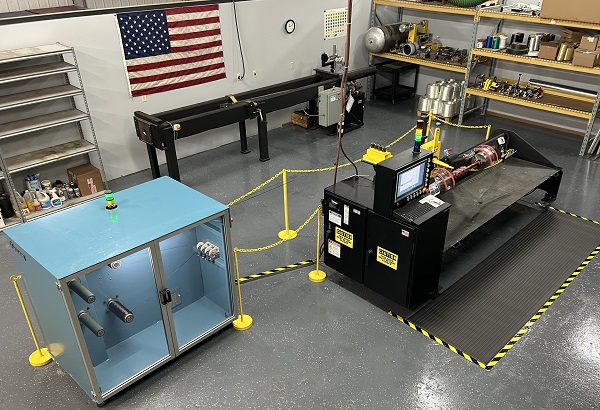

R&D Lab

In-House Filament Winding Training & Consulting

Assistance with winding techniques & part programming

McClean Anderson’s R&D Lab is devoted to customer education. We provide assistance in filament winding techniques and part program development.

Lab Features

- 4-axis Super Hornet filament winding machine with a maximum winding envelope of 760mm [30″] in diameter x 2000mm [79″] long.

- 4-spool Digital-Electronic Tensioning System. System accommodates standard 75mm [3″] core outside pull materials with a maximum spool size of 300mm [12″] diameter x 13.6 kg [30 lb]. Tension range: 9 N to 90 N [2 to 20 lbf].

- 8-spool stationary Bookshelf Creel. Spools of center-pull fiber are placed onto shelving and fiber is redirected through a series of ceramic eyelets.

- Forced air Curing Oven capable of 500F [260C] with data logging and thermal profiling.

- Wide variety of Wet-Winding and Towpreg fiber delivery tooling.

NOTE: Please contact us in advance to make shipping arrangements if customer specific materials (fiber and/or resin) are to be used for sample / test winding.